Mars Rover Robotic Arm 2019

Project Role: Team Lead

Northeastern's Mars Rover Competition Team is dedicated to contending in the University Rover Challenge. The challenge? "Design and build the next generation of Mars rovers that will one day work alongside human explorers in the field." From September 2018 to May 2019 I led the team of 4 engineering students devoted to designing the rover's robotic arm.

Problem Statement

Design and build a lightweight, low cost, durable, and maneuverable robotic arm to perform the extreme retrieval and equipment servicing tasks for the University Rover Challenge.

Requirements and Constraints

-

Pick up, carry, and drop off 5 kg objects

-

Perform precise maneuvers (flip switches, turn knobs, etc)

-

< 10kg

-

< $4,000

-

Compatible with the rover's electronics and software

-

Remote controlled

System Overview

-

5 Degrees of Freedom

-

Shoulder pitch and yaw

-

Elbow pitch

-

Wrist pitch and roll

-

-

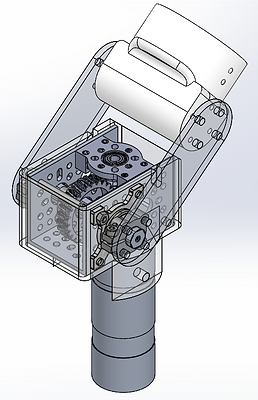

Custom built worm-drive gearboxes

-

3D-printed joint connectors

-

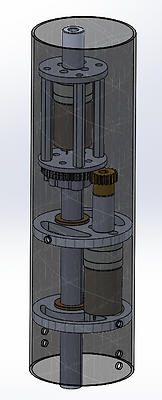

Slip-ring for continuous rotation of gripper

-

Linkage gripper system

Worm-drive gearboxes

When designing the power train for the arm, we estimated for a maximum torque output of 50 N-m. Since our arm needed to be lightweight and inexpensive, we decided to use high torque DC brushed motors and custom gearboxes designed with GoBilda parts.

A key feature of the worm-wheel gearboxes was that they are not backdrivable which meant we didn't need an external brake system. This design was also very cost effective. Though the design had its drawbacks. The tooth spacing between the worm-wheel and worm-shaft was very imprecise which caused a significant amount of backlash.

Wrist Rotation Mechanism

One of the challenges specified by the competition rules is fastening a screw. In order to do this the gripper must be able to complete several rotations. As a solution to this, I designed a mechanism incorporating a slip ring to allow for continuous rotation.

Though this design was effective for its intent, the slip ring used was unreliable and needed replacing just in the few months we were using it. Additionally, the design took up a lot of space and essentially made a third member. In future iterations, making the pitch and roll mechanisms of the wrist closer together would make this joint much more useful.

Competition Outcome

2019 was the first year that Northeastern ever participated in the University Rover Challenge (URC) and we were able to place 27/50 teams. We gained a lot of knowledge at competition that we could have only learned from experience. As Arm Team Lead, I'm excited to take everything I've learned and tackle this problem again for URC 2020.